135 1032 1270

Shenzhen Tepu Ke Electronic Equipment Co.,Ltd.

Contact: 135 1032 1270 (Miss Jiang)

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Product name: MPM125 solder paste printing machine /MPM125 fully automatic solder paste printing machine

Brand: MPM

Origin: USA/United States

Features of MPM125 solder paste printing machine :

The MPM Momentum BTB 125 solder paste printer is affordable and offers greater flexibility.

Can be used as a stand-alone in-line printer or configured with another Momentum BTB MPM125 solder paste printer to form two back-to-back printers to achieve dual-pass production. The Momentum BTB 125 solder paste printer offers outstanding performance due to its low initial investment plus With dual-pass capacity, the return on investment comes faster than competing presses.

The Momentum BTB 125 delivers the precision and repeatability found in expensive, high-end equipment.

The accuracy of the Momentum BTB 125 is the result of precision engineering, system integration and the design of the scraper delivery system, resulting in the Momentum BTB 125's superior performance at a relatively low purchase cost.

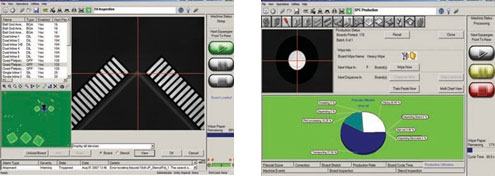

MPM125 Solder Paste Printer Advanced Inspection and SPC Tools

Momentum BTB 125 combines extended 2D inspection capabilities with MPM's unique contrast and texture-based technologies BridgeVision® and StencilVision™. As part of the powerful SPC programming tool, pad-level details can be viewed on the screen and device-level results are stored on each board. The combination of detailed processing information, expanded inspection capabilities and the fastest batching and post-printing equipment-level data collection allows your process engineers to effectively optimize the system and utilize equipment more efficiently.

When ease of use makes the device perform better, users can enjoy lower costs. The Momentum BTB125 is designed with the operator in mind, so it's easy to learn and even simpler to use. Speedline's Benchmark™ software, based on the familiar Windows® operating system, provides a convenient graphical user interface. Built-in intelligence provides guidance on all machine functions, applications and error fixes.

The MPM Momentum BTB 125 solder paste printer combines state-of-the-art technology, high reliability, industry-leading accuracy and ease of operation to set the value-leading standard for automated stencil printing.

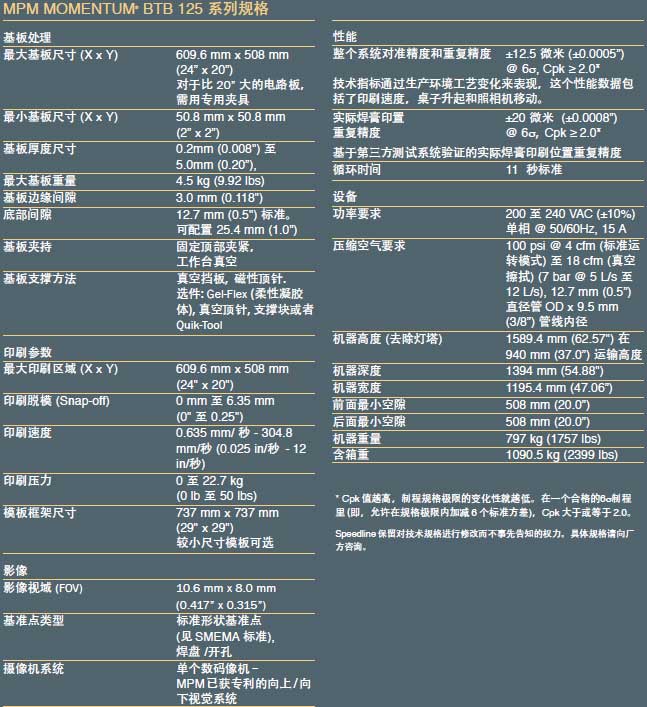

MPM125 solder paste printing machine parameters:

MPM125 solder paste printing machine : economical and practical

Industry-leading technology creates better equipment performance. MPM Momentum BTB125 contains all the features and subsystems to meet the high-yield requirements for lead-free printing of today's most difficult ultra-fine pitch components. As for the unknown challenges ahead, the performance of MPM Momentum BTB125 will continue to prove its unparalleled value.

The design of the template cleaning paper wrapped around the vacuum absorbing rod, Venturi vacuum, Zhuanli's solvent roller delivery system and full software control enable dry/wet wiping conversion to achieve excellent cleaning results.

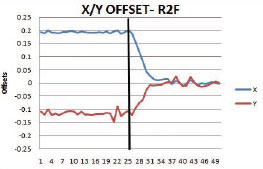

MPM125 Solder Paste Printer : SPI Print Optimizer, Speedline On our more advanced printing platform, a common interface has been developed to communicate with external solder paste inspection (SPI) systems to continuously monitor and adjust X, Y and θ Alignment to maintain target position.

MPM125 Solder Paste Printer: CANopen structure, fast signal transmission enables quick action control, making it easy to work in real multi-tasking environments, with greater output and minimal number of wires and cables.

MPM125 solder paste printer : Benchmark software is designed for ease of use, process flexibility and controllability. Benchmark has an intuitive interface and intelligent guidance to complete operating tasks. Step-by-step instructions and modular operation make installation and product changeover faster.

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Please submit your request and we will call you right back