135 1032 1270

Shenzhen Tepu Ke Electronic Equipment Co.,Ltd.

Contact: 135 1032 1270 (Miss Jiang)

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

JUKI placement machine RX-6R_RX-6B

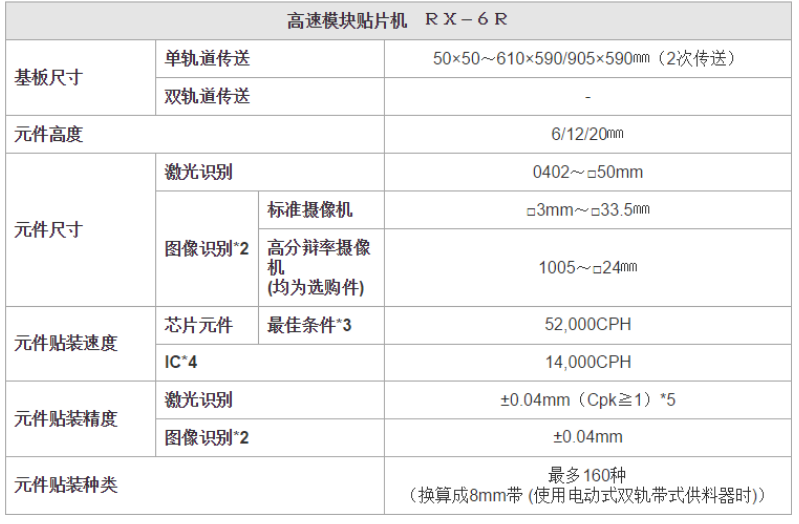

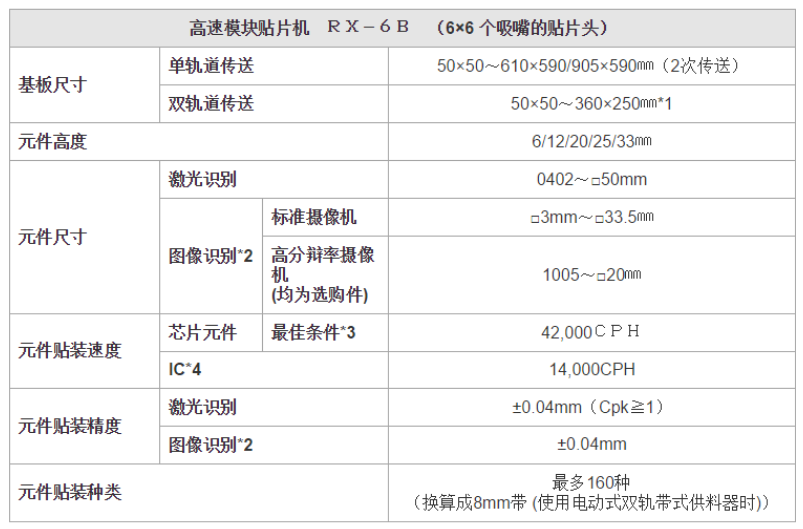

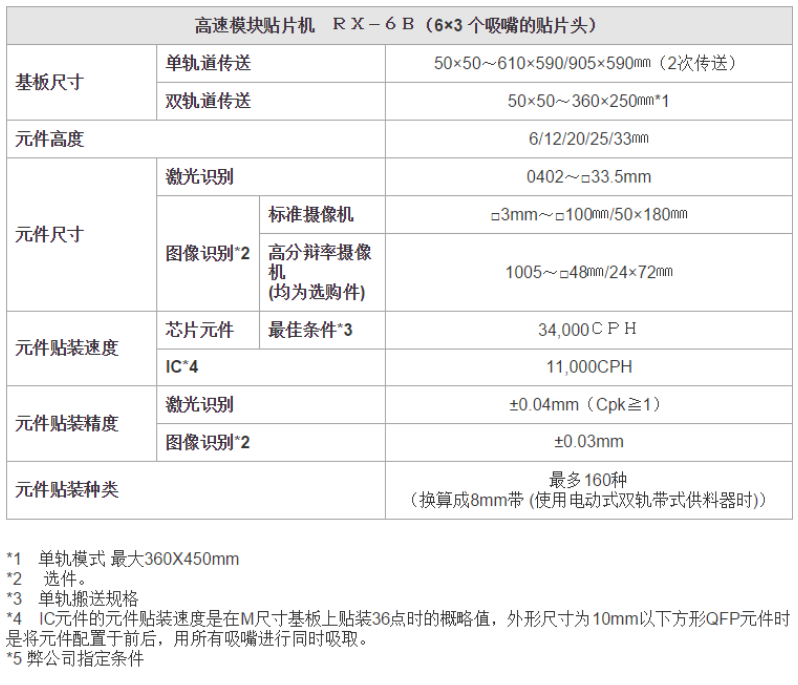

Component placement speed Chip components: 52,000CPH (better conditions)*2 IC components: 14,000CPH (IC)*3

Component size: 0402 (1005) chip ~ 50mm square component * 4 0402 (British 01005) chip ~ 50mm square component / 50 × 180㎜ * 5

Substrate size: Single track transmission: 50×50~610×590 / 905×590mm (2 times transmission) Dual track transmission: 50×50~360×250㎜/360x450mm (single track transmission)

Specifications of placement head 6×6 placement head with 6 nozzles 3×3 placement head with 3 nozzles*6

Compatible with dual-track production*6

Space-saving design with a width of 1.25m

Standard-equipped pick-up/placement monitor inspection function enables higher quality*1

By replacing the placement head, you can build a better production line that can adapt to changes in production varieties.

High-speed placement achieved through pause-free image recognition

Compatible with ultra-high components, large components, and large substrates

The new matrix tray server TR8S improves component response capabilities and productivity.

Remark

*1 Only compatible with RX-6B 6-nozzle placement head

*2RX-6R

*3 Options

*4 RX-6R/RX-B 6×6 nozzle placement head

*5 RX-B 6×3 nozzle placement head

*6 Only for RX-6B

RX-6R is a new model added to the RX-6 series. Due to the improved axis of the nozzle moving up and down, increased strength, and optimized height of the placement head, the placement speed is significantly higher than that of previous machines. Land increased by 24% to 52,000CPH (better conditions).

The RX-6 series can not only be used to mount very small components, large components, and back-height components, but can also be used to mount large substrates. It is highly versatile and saves space. It is only 1.25 meters. width, contributing to your space-saving production.

The high-speed model RX-6R is included in the RX-6 series, making the composition of the production line softer and more flexible. It can not only correspond to multi-variety production, variant variable production, but also correspond to mass production, that is, it can correspond to diverse production. requirements.

Features:

Higher placement speed 52,000CPH

The axis of the nozzle moving up and down has been improved, the strength has been increased, and the height of the placement head has been optimized. Although the volume width is only 1.25 meters, the placement speed has been greatly increased by 24% compared with the previous machine, reaching 52,000CPH. (better conditions).

Substantial component compatibility and substrate compatibility

JUKI's unique laser head can handle square components from 0.4mm × 0.2mm to 50mm and components with a height of 20mm.

The substrate size can correspond to various substrates ranging from 50mm×50mm to 610mm×590mm.

It can handle large substrates with dimensions of 910mm x 590mm when being transferred and mounted in two separate passes.

Specification

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Please submit your request and we will call you right back