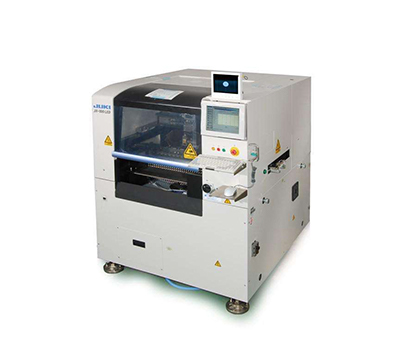

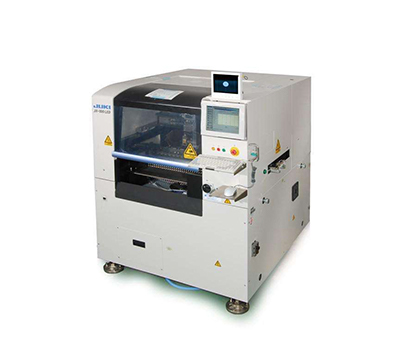

JUKI JX-300LED LED general placement machine

The new JX-300LED model can not only produce the most suitable LED substrates, but is also fully capable of producing LED power substrates and other consumer electronic products. The actual placement efficiency of the new JX-300LED model has increased by 10% based on the KE2070 model, and the actual production capacity has reached more than 18,000CPH.

Extended specification substrate (1500×360mm)

Mounted component height: 6mm / 12mm

Mounted component size

Laser laser identification: 0.6x0.3mm (English 0201) ~ 33.5mm

Mounting speed: Better conditions: 0.155 seconds/chip (23,300CPH )

Mounting accuracy: Laser recognition: ±0.05mm (±3σ)

Mounting component types: Mechanical feeder: 40 types (8MM)

Device size (W*D*H): Standard specifications: 1,920×1,393×1,440mm

device Weight: about 1,420Kg

Specifications

Operating system: WINDOWS XP (Chinese, Japanese, English language switching)

Substrate size: Standard specification substrate (1200×360mm)

Features

1. JX-300LED is suitable for the production of 1200 ~ 1500mm LED lighting substrates and LENS LCD screens.

JX-300LED’s unique 2- and 3-time splinting functions enable the production of ≦ 1500MM LED substrates, and the substrates are fully automatically visually aligned through 3 sets of MARK points. , achieving high-precision placement.

2. JUKI's unique laser patch monitoring function

JUKI's unique mounting head is equipped with a laser sensor to detect the presence of components on the mounting head in real time. For LED devices with adhesive properties on the component surface, the blowing time can be set to prevent the LED components from being brought back. Through the laser real-time monitoring function, it is possible to prevent components from falling off and sticky LED components from being brought back before placement.

3. JUKI’s unique laser positioning, identifying LENS pins

JUKI’s unique LNC60 laser three-dimensional scanning imaging technology takes side photos of the LENS pins through 360-degree rotation, and draws the component appearance based on the component image edge and rotation angle. And calculate the component center, angle and size to complete the direction judgment of the LENS, and finally complete the X, Y, and angle identification of the LENS for high-precision LENS placement.

LED placement machine JX-300LED is the most suitable LED placement machine for the production of LED lighting machines or medium and large LCD backlight sources.