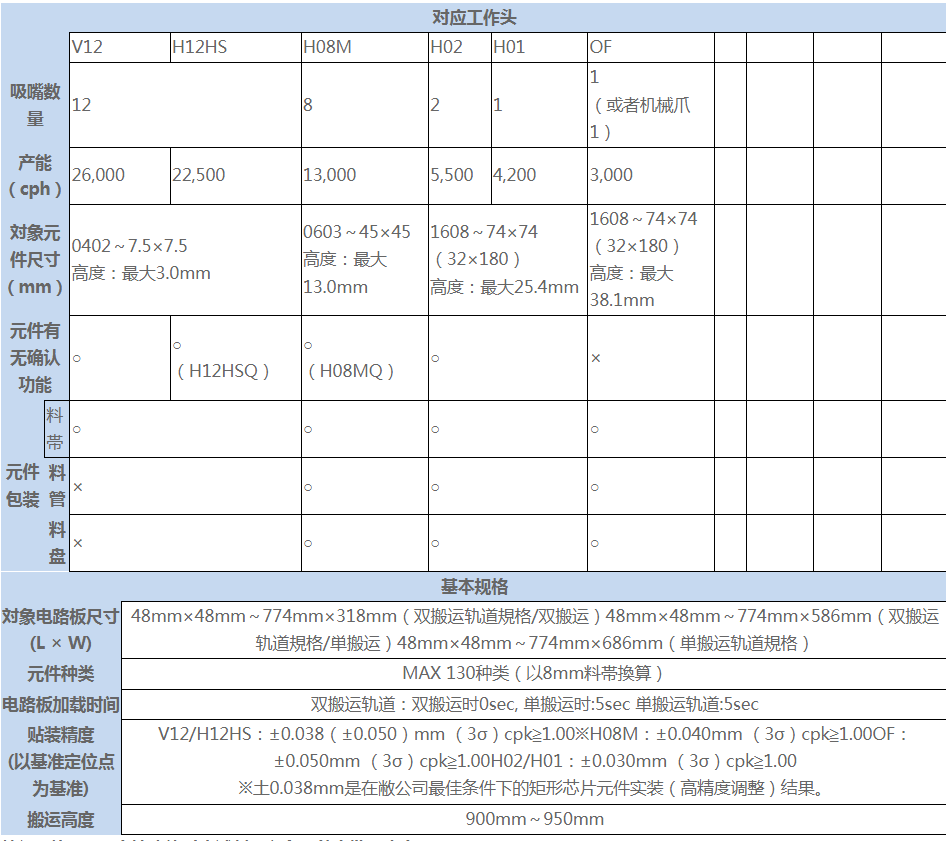

fuji/Fuji placement machine AIMEX IIS extended All-in-one placement machine (AIMEX2s) parameters

Feature 1

Use the NPI support function to support prototypes and high-variety, low-volume production

Component data can be created automatically on the machine.

When creating a production program, the most time-consuming component data can be automatically created, so image processing errors that occur on the first product when starting a prototype production line or switching production types can be quickly responded to.

Feature 2

Can carry up to 130 types of tape components

Because it can carry a large number of tape components, it is the most suitable machine for multi-variety production. In addition, tray loading and tube loading are also available.

The material tray unit-LTW can be mounted on either of the two feeding platforms.

The tray unit-LTW can carry up to 48 types of tray components and 27 8mm feeders.

Larger can correspond to a component height of 38.1mm (1.5 inches)

Feature 3

Adopting dual tracks to correspond to independent production

The use of dual transport rails corresponds to the dual-rail production of different types of circuit boards. (option)

At this time, when one side of the track is in production, the other side of the track can be changed, which reduces the time of line change.

In addition, even dual-rail transportation can handle circuit boards with a larger size of 774x318mm.

Feature 4

Uses the same unit as the NXT series

The placement work head, feeder, image processing camera and other main units adopt mature units in the NXT series.