1936MK5 reflow oven

Detailed introduction of HELLER reflow soldering mk5 series:

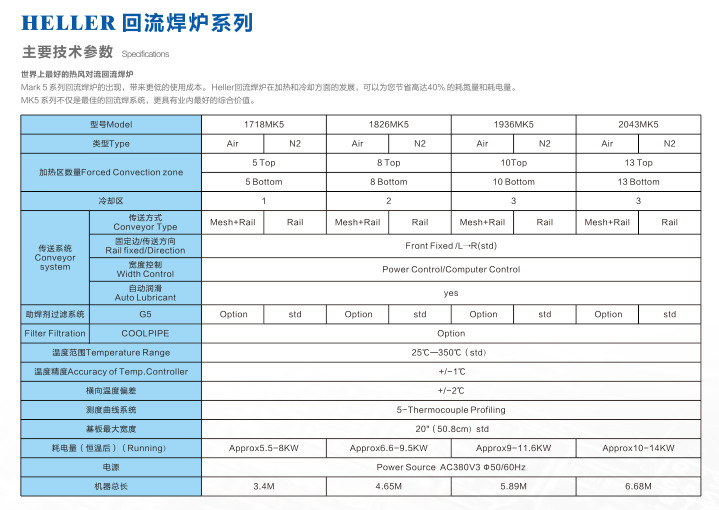

MK5 series | total length | Number of heating zones/total length of heating zones | Number of cooling zones |

1826MK5 reflow oven |

| 465 cm (183 inches) | 8 upper heating zones/8 lower heating zones | 2 upper cooling zones (standard option), lower cooling zone/external cooling (optional) |

260 cm (102 inches) |

1936MK5 reflow oven |

| 589 cm (232 inches) | 10 upper heating zones/10 lower heating zones | 3 upper cooling zones (standard option), lower cooling zone/external cooling (optional) |

360 cm (141 inches) |

2043MK5 reflow oven |

| 668 cm (263 inches) | 13 upper heating zones/13 lower heating zones / | 3 upper cooling zones (standard option), lower cooling zone/external cooling (optional)/ |

430 cm (170 inches) |

Features:

American HELLER lead-free reflow soldering, HELLER vertical curing oven, HELLER vacuum reflow soldering equipment. There are a full range of products including HELLER 1809MK3, HELLER1913MK3, HELLER1936MK5, HELLER1707MK3, HELLER1807mk5, HELLER1826MK5, HELLER reflow 2043MK5, etc. HELLER reflow soldering is a more cost-effective imported reflow soldering, and HELLER reflow soldering is energy-saving and efficient.

The HELLER1936MK5 and HELLER2043 MK5 systems achieve higher reproducibility through lower delta Ts. The latest breakthrough in the Mark 5 reflow oven system further reduces customer acquisition costs. Heller's new heating and cooling improvements will reduce nitrogen consumption and electricity consumption by 40%. The MK5 series is not only a better reflow soldering system, but also has the best overall value in the industry!

Shenzhen Topco Electronic Technology Co., Ltd. specializes in providing the following SMT equipment to electronic manufacturers:

MPM printing machine , Koh Young SPI , Ersa stencil printing machine , placement machine rental

Siemens placement machine , FUJI placement machine , Panasonic placement machine , Yamaha placement machine , Universal placement machine

Meilu AOI , Vitronics Soltec reflow soldering, non-standard automation equipment

The entire SMT production line equipment, as well as SMT spare parts, SMT supporting materials, services and solutions.