By continuously strengthening the overall pick-and-place process and introducing a new lightweight feeder, the iX system has a pick-up rate of more than 99.99%, higher placement of passive components (35 microns), and improved camera-aligned component production capacity. 25%.

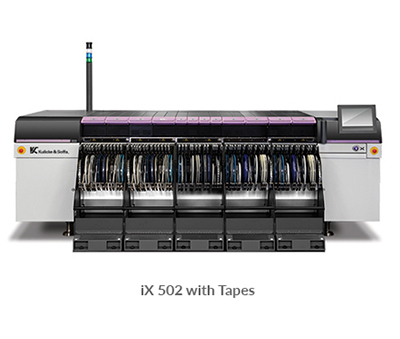

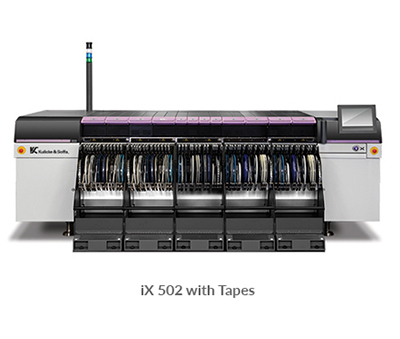

Through software optimization of factory process procedures, iX 302 and iX 502 can be easily added to customers' factories. The modular design concept simplifies operation while enhancing overall control in mass production environments.

The unique performance of iX , the industry's best placement control process,

can strictly control every placement, achieving the industry's highest yield rate, thereby lowering costs. High-quality products enable our users to meet the needs of end customers.

The unique mounting process is reflected in:

Advanced PCB collision detection

No impact = no component cracking

Pressure control of closed loop placement

Placement process inspection (according to blue-print value), each placement can be inspected

PCB surface mapping allows other placement heads to be mounted without affecting the placement height.