135 1032 1270

Shenzhen Tepu Ke Electronic Equipment Co.,Ltd.

Contact: 135 1032 1270 (Miss Jiang)

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

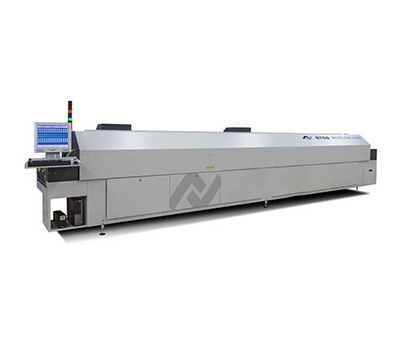

ISA reflow soldering 4/26

Ersa hot air reflow soldering 4/26 is currently the leader among the new generation of Ersa reflow soldering systems to achieve greater soldering quality and performance at lower production costs.

Kurt-Esa was founded in 1779 and has a history of 238 years. It was originally established as a forging hammer factory. Currently, Kurt-Esa is a highly competitive medium-sized industrial group with factories The company has more than 1,000 employees throughout Germany and abroad. Kurt-Essa officially entered the Chinese market in 1985. Over the past thirty years, its business has developed rapidly, and its equipment has won the trust and good reputation of customers. Ersa reflow soldering has become the industry standard for setting high-end reflow soldering equipment. .

Ersa has strong technical strength and profound cultural heritage.

Ersa's Hotflow series leads the industry with an overall 25% energy saving and a 20% reduction in N2 consumption. The flagship model Hotflow 4/26 provides 26 temperature zones and a process length of more than 7 meters. The smallest Hotflow4/8 can reach 8 temperature zones and a process length of 3.62 meters.

The full range of Hotflow includes:

Hotflow4/26, Hotflow4/20, Hotflow4/14, Hotflow4/8,Hotflow3/20, Hotflow3/20e, Hotflow3/20 Voidless, Hotflow3/14 and Hotflow3/14e

German ERSA reflow soldering

Features:

1. Excellent thermal performance and thermal balance reflow soldering system

2. By optimizing the motor, an independent controllable process area is achieved.

3. Multi-level control cooling system

4. Purify the air through multi-stage high temperature decomposition of air

5. Residual oxygen monitoring and control, low nitrogen consumption

6.ERSA process control software (EPC)

7. The software automatically generates temperature curves

8. Multi-track system (1-4), adjustable 1-3 times

9. Support invisible center heating

10. Continuous low power consumption operation

11. Can be used for PCB board clamping and transportation systems of different specifications

12. Automatic profiler that automatically and quickly generates temperature curves offline

Product parameters:

Equipment size: length*width*height: 6,600 mm*1,410 mm*1,350 mm

Equipment weight: 2,600 kg

Workbench width: automatically steplessly adjustable, adjustable range 45-560 mm

Delivery system:

Clear transfer height: 32mm/- 40mm

Center support, automatic stepless adjustment

Conveying speed: 20-200 cm/min

Conveyor chain pin length: 3/4/5mm

Process temperature zone

Process length: 5920 mm

Heating length: 3805 mm

Cooling length: 2115mm

Heating system

20 convection heating boxes (preheat zones up to 14, reflow zones 6)

Volumetric flow per module adjustable up to 500 m3/h

Rated power of a single module: 3.3 kW

cooling system

4 cooling zones with water return

Power parameters

400V, 3 phase, N, ground, 50/60Hz

Exhaust system:

With monitoring function, air extraction capacity up to 2x 300-600 m3/h

describe:

The Ersa hot air reflow 4/26 reflow soldering system is designed and manufactured entirely from steel, weld sealed, powder coated and has internal electrical cabinets and computer operating terminals. Features include electric lid opening, quick-change convection heater box, multi-level process gas purification and a powerful and high-performance cooling zone.

option parameters

1. The chain conveyor can convey 3/4/5mm pin length

2. Pin and chain conveyor with 3/4/5mm pin length

3. Low-quality center-supported pin chain conveyor

4. Electric adjustment of conveyor width and center support

5. Up to 4 years of tracking system support in the center (1x fixed, 3x variable)

6. Zhuanli clamping and conveying system for flexible boards

7. With a monorail system, it is possible to use low-quality tubular supports.

8. Ambient air or nitrogen operation

9. The cooling zone of the system can be equipped with an integrated cooling system and external cooling aggregates

10. Cooling can be cooling aggregates or local water connections

11. Pyrolysis multi-stage condensation management system

12. The heating and cooling boxes are removable without tools.

13. Energy consumption management

Shenzhen Topco Electronic Technology Co., Ltd. specializes in providing the following SMT equipment to electronic manufacturers:

MPM printing press , Koh Young SPI

Panasonic placement machine , Fuji placement machine , Siemens placement machine

Meilu AOI , Vitronics Soltec reflow soldering

The entire SMT production line equipment, as well as spare parts, services and solutions.

135 1032 1270

Contact: Miss Jiang

Mail box: market@topsmt.com

Address: 201, Building 4, Innovation Port, Hanyu Bay, Fuhai Street, Baoan District, Shenzhen

Please submit your request and we will call you right back