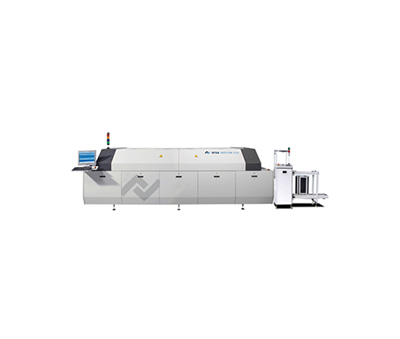

German ERSA reflow oven

Outstanding thermal performance, better energy balance, better process control, and higher machine startup rate!

The new HOTFLOW is a third-generation machine based on the proven Ersa multi-point nozzle proprietary heating technology. Early in the development phase of the HOTFLOW series machines, designers focused on improving heat transfer efficiency, reducing energy and N2 consumption, improving cooling effects and optimizing process control by completely redesigning the process tunnel.

Whether in terms of production efficiency or floor space, HOTFLOW is worthy of being the industry benchmark. Increase production capacity by 4x without increasing floor space with its dual, triple and now quadruple options! In addition, different speeds and PCB widths can be set for each track, allowing for greater production flexibility.

Currently, the machine can be set to four different speeds and track widths to handle three different products simultaneously. To ensure higher machine availability, we only use higher quality materials. Finally, all major component replacements can be completed in minutes, reducing machine downtime to a minimum.

Unique technical advantages:

1. Lightweight track technology: The track is the smallest and thinnest, can be transmitted on two tracks, three tracks and four tracks, with small temperature difference and no deformation.

2. Multi-point nozzle technology: good temperature uniformity, high heat transfer efficiency, and good guidance of hot air flow

3. Bubble removal function: Use the radio wave generator to remove bubbles, which can reduce more than 80% of bubbles.

Shenzhen Topco Electronic Technology Co., Ltd. specializes in providing the following SMT equipment to electronic manufacturers:

MPM printing press , Koh Young SPI

Panasonic placement machine , Fuji placement machine , Siemens placement machine

Meilu AOI , Vitronics Soltec reflow soldering

The entire SMT production line equipment, as well as spare parts, services and solutions.